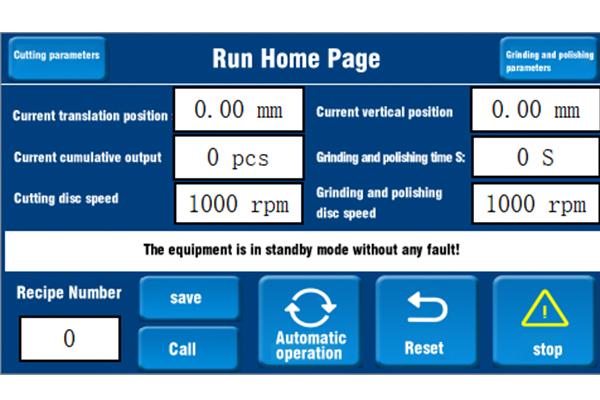

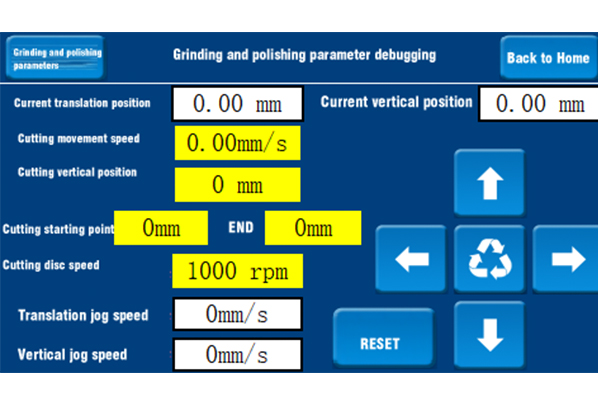

1. Easy sample preparation, no resin solidification This system only takes 3 to 5 minutes to prepare a sample, saving you a lot of time and improving work efficiency. The traditional resin solidification method is to first solidify the sample with resin, cut the resin, coarsely grind, and grind it. It takes several hours to make a sample, and it will affect the measurement accuracy. |

2. The terminal fixture can fit terminals of various sizes The newly developed fixture can fit terminals of various models. There is no need to worry about the wire teeth being deformed or the core wire flying out during cutting and grinding. No special skills are required. The software operation is accurate and fast. One-click start completes the calculation of values and prints the corresponding report. The operation is simple and convenient, while improving work efficiency. |

a) Ambient operating temperature: -20℃~+40℃. |

b) Relative humidity of the operating environment: |

a) Mechanical component configuration: · 1 pair of terminal special clamps, range 0.8mm²~150mm² (clamping diameter 1MM-14MM) · 3 matching cutting grinding wheels · 100 matching grinding sandpapers · 1 bottle of image restoration cleaning fluid (50ml) |

b) Image imaging system configuration: · Terminal cross-section microscopic analysis magnification: 0.7-4.5X or 1-5X (6 levels), total video magnification: about 30X-300X · 1 set of high-definition industrial USB 2.0 video system with 3 million pixels. · 1 cold light LED with full white adjustable lighting device. |

c) Special analysis software configuration: · 1 set of the latest terminal special software (Chinese), free upgrade. (Note: The software is set to VW60330 standard. different industry standards can be set according to the user's standards) · 1 high-precision calibration ruler 10mm/0.1mm× (precision: 1um). |

d) Computer · Intel CPU Dual Core - 4GB RAM - 500G Hard Drive · 19-inch LCD Monitor - DVD Drive - Windows 7 Simplified Operating System |

1. Precision automatic cutting table | 2. Precision automatic grinding table |

3. Scope of application of wire terminals: | 0.8m㎡~150m㎡ |

4. Power supply: | AC220V/50HZ/750W |

5. Cutting disc specifications: | Φ110*0.5mm |

6. Screw type clamp: | Maximum clamping diameter 14MM· |

7. Security door: | Lift the cover and the machine stops. |

8. Machine size: | 380*465*333MM (length*width*height) |